Initial Contact

In September 2023, I was excited to receive an inquiry from New Zealand about setting up a 500 kg French fries production line. During my first phone call with Mr. Chen, I discovered that he was also Chinese, which made our communication more direct and friendly. Mr. Chen suggested we continue in Chinese, making our conversation more efficient and pleasant. During our nearly 13-minute call, we discussed the key details of the French fries production line in depth.

Challenges Encountered

Although we initially reached a consensus, the project soon encountered a space issue. Mr. Chen’s current workshop is only 300 square meters, while an ideal French fries production line requires at least 500 square meters. This meant Mr. Chen needed to find a larger workshop to meet production requirements.

Solutions and Progress

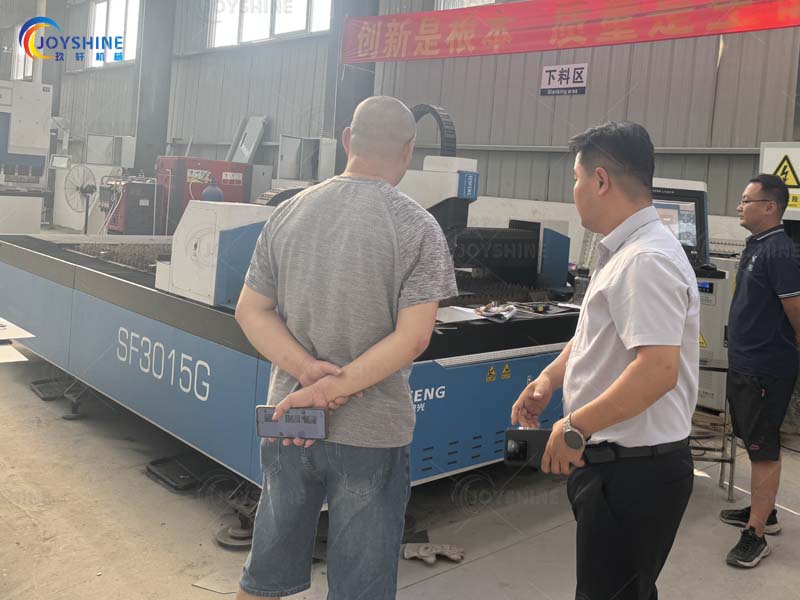

The project was temporarily put on hold. In June of this year, Mr. Chen contacted me again to express his intention to restart the French fries production line project. He arranged for a friend in China to visit our Joyshine factory for an on-site inspection. While online descriptions were impressive, verifying the actual conditions was crucial. During the visit, his friend highly praised our factory and office environment, stating that our professionalism exceeded online descriptions. This greatly enhanced Mr. Chen’s trust in us.

Successful Collaboration

After finalizing all the details, we successfully signed an $182,000 order. Mr. Chen was impressed with our quick response and professional service and promptly arranged the deposit payment. Our first collaboration officially began.

Main Equipment Configuration

The project includes the following key equipment:

Air Dryer: Removes surface moisture from the fries to ensure optimal frying results.

Oil Extractor: Removes excess oil from the fried fries.

This collaboration not only enhanced my understanding of the international market but also validated Joyshine's capability in quick response and professional service. I am looking forward to bringing more successful cases like this in the future.

— Jany, Sales Representative, Joyshine Machinery