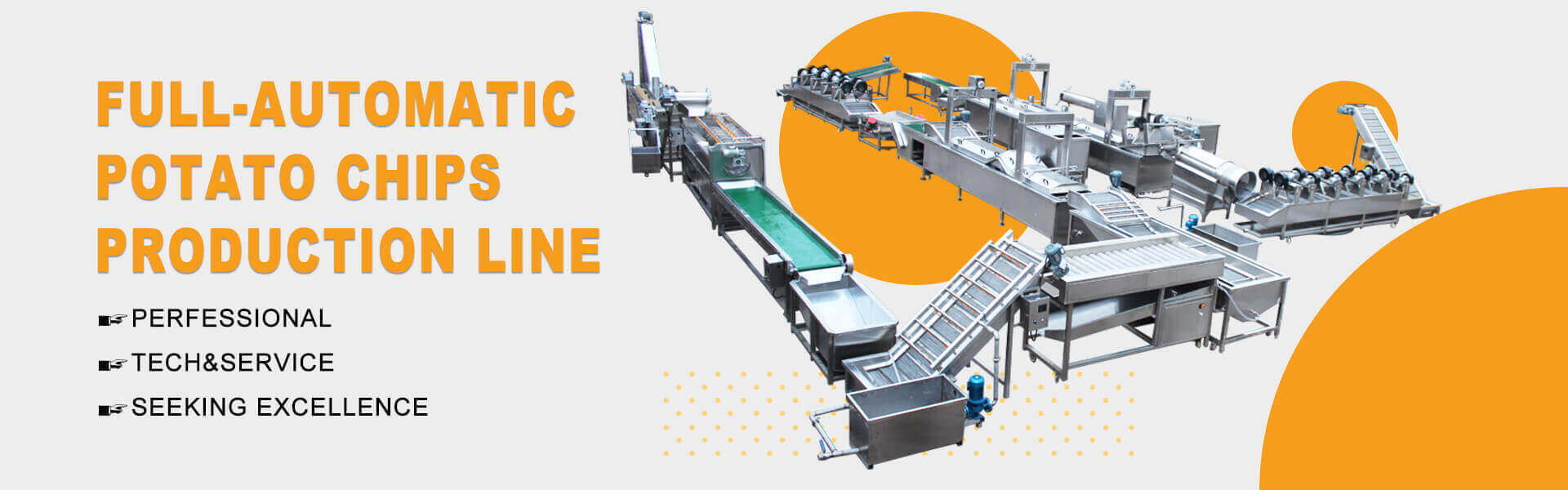

Automatic Potato Wedges Production Line

Description:

This potato wedges processing line is designed for medium to large-scale food factories, with a production capacity ranging from 300 kg to 2000 kg per hour. It covers the full process from washing, peeling, cutting, blanching, air drying, frying, de-oiling, freezing to packaging. The line is highly automated, stable in operation, and customizable to meet specific needs. It is suitable for processing potatoes, sweet potatoes, cassava, and other root vegetables.- Description

- Advantage

- Parameters

- Application

- Video

Parameters

|

No. |

Name |

Quantity |

|

1 |

Elevating Conveyor |

1 set |

|

2 |

Potato Washing and Peeling Machine |

1 set |

|

3 |

Picking Line |

1 set |

|

4 |

Potato Wedging Machine |

1 set |

|

5 |

Bubble Washing Machine |

1 set |

|

6 |

Blanching Machine |

1 set |

|

7 |

Air Drying Machine |

1 set |

|

8 |

Elevating Conveyor |

1 set |

|

9 |

Continuous Belt Frying Machine |

1 set |

|

10 |

Vibrating Deoiling Machine |

1 set |

|

11 |

Air Drying Machine |

1 set |

|

12 |

Elevating Conveyor |

1 set |

|

13 |

Freezing Machine |

1 set |

|

14 |

Automatic Packing Machine |

1 set |

1. Target Users & Usage Scenarios

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback:

hot products