Industrial French Fries Cutting Machine

Description:

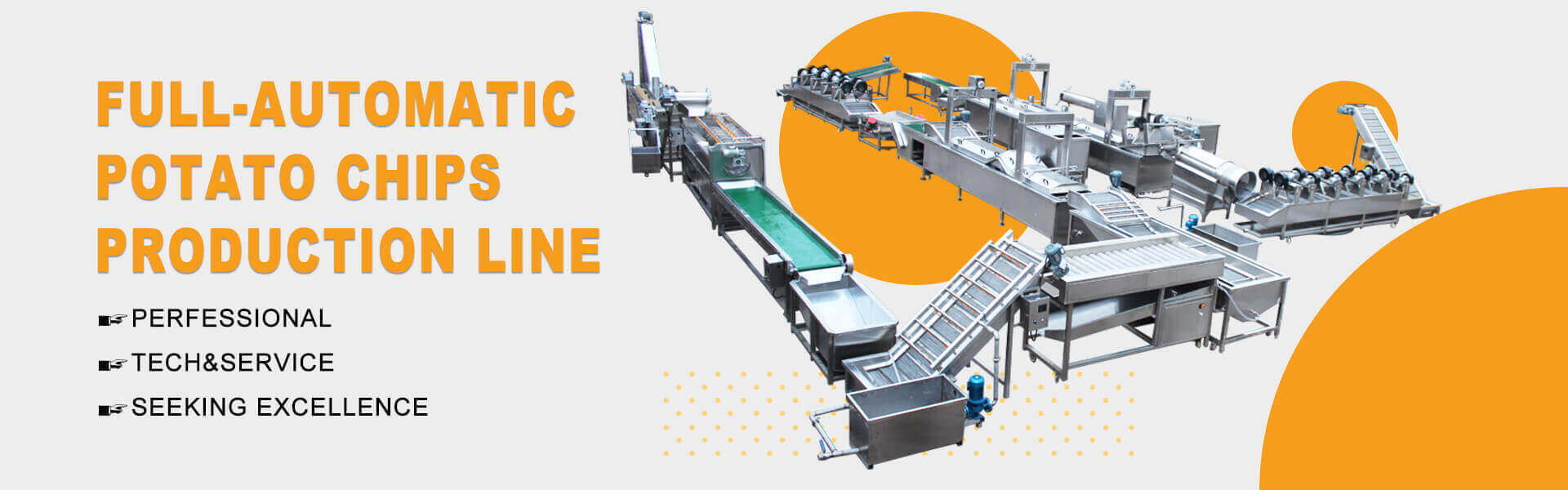

This kind of machine belongs to potato chips production line. It mainly cut potatoes into strips. Then through other process making potatoes into potato strips which we can make potato chips. After cutting, the strips can be put into next step for washing, scalding and frying, it is the most important step in the whole processing line. For this machine, it is made of stainless material so that it is maintained easily.Products advantage and features:

- 1. Cutting speed fast and shape complete, smooth edge without crack.

- 2. Wide cutting range, from 7-20mm by changing the cutter knives.

- 3. It is suitable for various kinds of rot vegetable.

- 4. Discharging direction could be flat or bent down.

- 5. High efficiency, simple appearance and structure and easy to operate.

- Description

- Advantage

- Parameters

- Application

- Video

Description

With high-speed stainless steel blades, this industrial potato chip slicer is designed for efficient cutting and is commonly used in potato chip production lines. It can process up to 500 kilograms of potatoes per hour and can quickly cut them into uniform potato chips, which significantly improves production efficiency, reduces labor costs and helps companies make profits. The cutting size ranges from 7mm to 20mm and users can easily change the cutting size by simply adjusting the blade to meet various market needs. The discharge direction of the equipment is flexible and can be parallel or curved to facilitate further processing and packaging.

Advantage

- 1. High-efficiency cutting: Equipped with high-performance stainless steel blades and advanced cutting technology, the cutting speed is fast and can meet the needs of large-scale production. The cutting capacity can reach more than 500 kg per hour, ensuring stable product quality.

- 2. Adjustable cutting thickness: According to customer needs, the cutting thickness can be adjusted within the range of 7-20 mm, flexibly adapting to market changes.

- 3. Sturdy and durable: The equipment is made of food-grade stainless steel, which meets international health standards, ensures safety and reliability, and is resistant to corrosion and wear.

- 4. Easy to clean and maintain: The modular design makes the disassembly and cleaning process of the equipment simple and quick, ensuring a hygienic production environment.

Parameters

|

Model |

Dimension(mm) |

Power(kw) |

Capacity(kg/h) |

|

JSSTJ600 |

950*800*950MM |

1.1 |

400-500KG/H |

Application

This cutter is widely used in potato chips production lines, especially in fast food restaurants, catering services and large food processing plants, and can quickly respond to market demand. It is not limited to potatoes, but can also be used to cut other root vegetables, such as sweet potatoes, taro, radishes, carrots and cassava, etc., to meet the diverse needs of customers.

Video

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback:

hot products