Semi-automatic Potato Chips Production Line

Description:

This set of production line is mainly for potato chips processing. It can make potato cut into strips and chips easily. But it needs people to operate. Compared with fully automatic french fries potato chips production line, it is the first choice for small process enterprise.Product Advantage:

- 1. Its capacity is about 30-500kg/h. Meanwhile, we can accept customized service.

- 2. Heating method: electric or gas heating you can choose.

- 3. It is easy, safe and hygienic to operate.

- 4. The materials are from excellent stainless steel.

- 5. Final products: potato chips, french fries and banana chips.

- Description

- Advantage

- Parameters

- Application

- Video

Description

This set of production line is mainly for potato chips processingny by Joyshine. It can make potato cut into chips easily. But it needs people to operate. Compared with fully automatic potato chips production line, it is the first choice for small process enterprise and small business.

Potato chips mini plant is also known as small potato chips plant or semi-automatic potato chips line. It is a small scale potato chips manufacturing line with semi-automatic chips making machines. In automatic potato chips line, all the processes can be done automatically by machines even the product handling process. While in small chips making plant, the product may be handled manually from one process to the next. Due to this fact, this small plant for chips making is suitable for businesses that need small production capacity. And it is also the perfect choice for people who want to build a start-up business. As we all know that potato chips making is a profitable industry, and crispy chips are favorite snacks among the young and the old. Joyshine machinery offers tailored solutions for small potato chips line with high quality machines as well as rich professional knowledge.

Work flow of semi-automatic potato chips production line

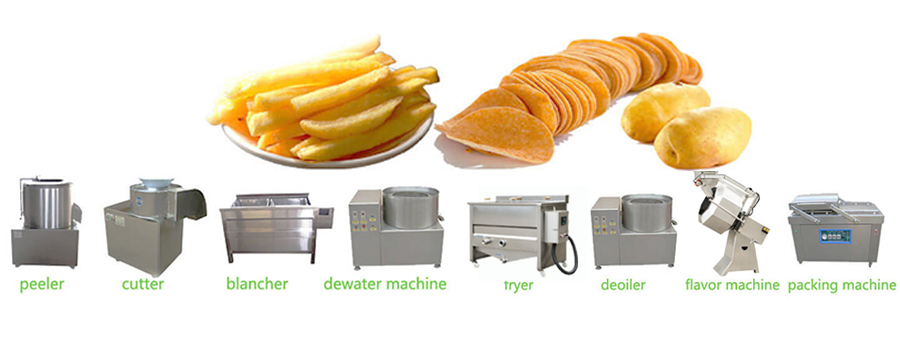

Potato washing and peeling machine → potato slicer machine → blanching machine → dehydrator → deep fryer → deoiling machine → seasoning machine → packing machine

Introduction of different potato chips making machine

Potato washing & peeling machine: used to clean and peel the skin of potatoes in energy-conserving and high efficient way.

Potato slicing machine: slice the potatoes into slices and bar shapethe thickness can be adjusted according to your preference.

Chips blanching machine: this is used for blanching the potato chips and making them look more attractive keeping fresh.

De-watering machine: with centrifugal for saving the time of frying and make the chips more delicious.

Chips Frying machine: adopt water & oil mixture frying machine after the operation is finished. You just need to release the water at the same time the residue will flow outside together with the water greatly increasing the oil's using recycle.

De-oiling machine: reduce the oil content of potato chips and make preparation for flavoring process.

Flavoring machine: adopt spray method, seasoning the potato chips evenly. and the potato chips are not easy to break.

Potato chips packing machine: inflate the nitrogen into bags white packaging potato chips. It could finish inflation, packaging and printing one time.

Advantage

- 1. Its capacity is about 50-150kg/h. This process line is preferable for small chips making business. And it is an ideal opportunity for you to start your ow business.

- 2. Heating method: electric or gas heating you can choose.

- 3. Esay operate and maintance: It is easy, safe and hygienic to operate.

- 4. The materials are from excellent stainless steel.

- 5. Final products: potato chips, french fries and banana chips.

- 6. Tailor-made solutions. A reliable process line is a success factor for your potato chips making business. We offer customized turnkey solutions for you to get the optimum result.

- 7. Premium machines. Small as it is, the potato chips mini plant consists a series of robust and clean machines. Most of the machines are made of stainless steel 304, ensuring safe and hygienic environment for the chips processing.

- 8. Competitive prices. With our all engineering and production team, we can offer you quality machines with reasonable prices.

-

9. Great flexibility. In the small potato chips plant, all the machines specially designed so that they can be easily installed, cleaned and maintained.

Parameters

|

Device machine |

Power(kw) |

Dimensions(mm) |

|

Cleaning machine |

1.5 |

700*630*950 |

|

Potato chip fries machine |

1.1 |

900*850*1000 |

|

Mesh belt blanching machine |

24 |

1000*500*1000 |

|

Dehydrator |

1.5 |

1000*600*740 |

|

fryer |

36 |

1200*1000*1200 |

|

deoiler |

1.5 |

1150*600*740 |

|

Seasoning machine |

1.1 |

1150*800*1300 |

|

Packing machine |

1.5 |

800*500*1000 |

Application

1. People can use it in many places, such as small process enterprise, food factory, etc.

2. It is can be used for all kinds of root vegetables and fruits, potato, carrot, apple, banana etc.

Video

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback: